A very impressive Northern Crucible event was held at Casa Hotel Chesterfield on the 18th of June, 2019. The purpose of the meeting was to discuss various ways of smart manufacturing and energy saving, in particular in heavy industry, such as metallurgy, foundries or anyone who uses furnace type equipment. As usual, the event attracted a melting pot of manufacturers, academics and service providers, who together represent the shared enthusiasm, knowledge and experience to push boundaries and ensure continuous improvement.

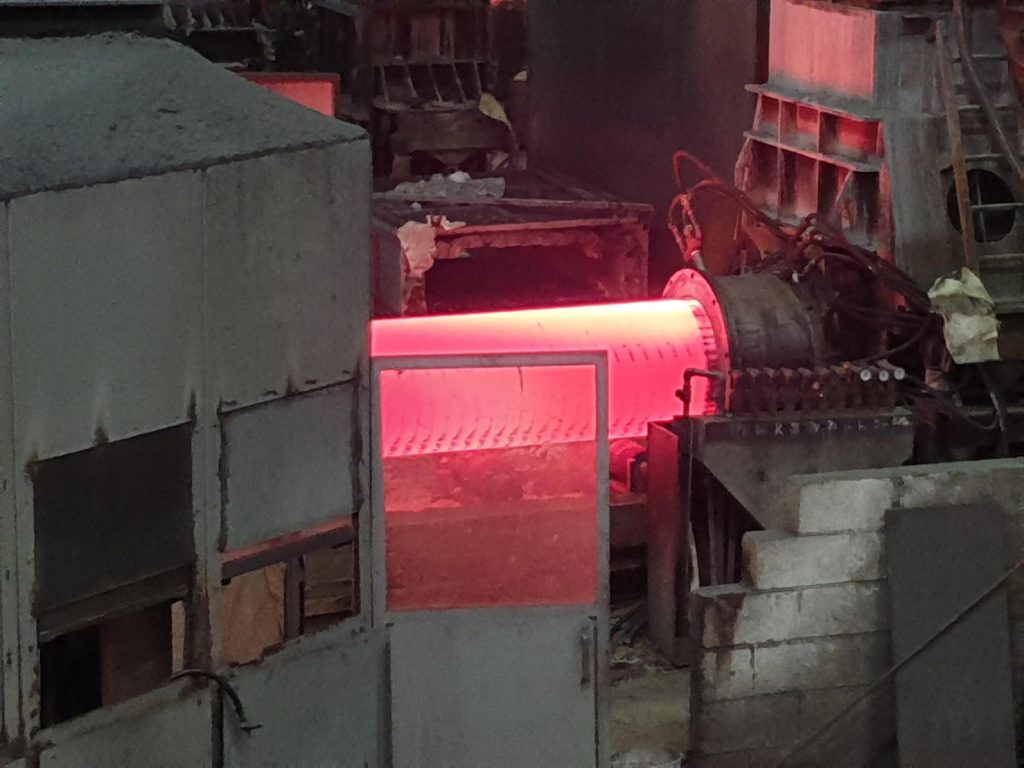

The highlight of the event was a very engaging site visit to United Cast Bar, where we all got to witness a remarkable process of casting the record-breaking diameter iron bar in the world. The complex process was timed specifically to coincide with our visit, so the attendees were able to see it for themselves. James Brand, the MD of the company, has shared his experience in using an innovative method allowing 15% energy saving in their cast processes. James was also happy to share this good practice with other companies.

On return to Casa, we had a detailed discussion of the observed method with the supplier of the energy-saving system currently used at United Cast Bar. The Question and Answer session involved most of the audience in participation, which indicated the importance of the topic to the local industry.

The continuation of the event saw academic input from Ben Steer (University of Sheffield, Engineering student) and Dale Riahi (AMRC, PhD student), who discussed further smart technology and new ways of making production even more efficient. As part of Norther Crucible, academic perspective is always there for manufacturers in order to break barriers between cutting edge technology fresh from scientific papers and its implementation in the real world.