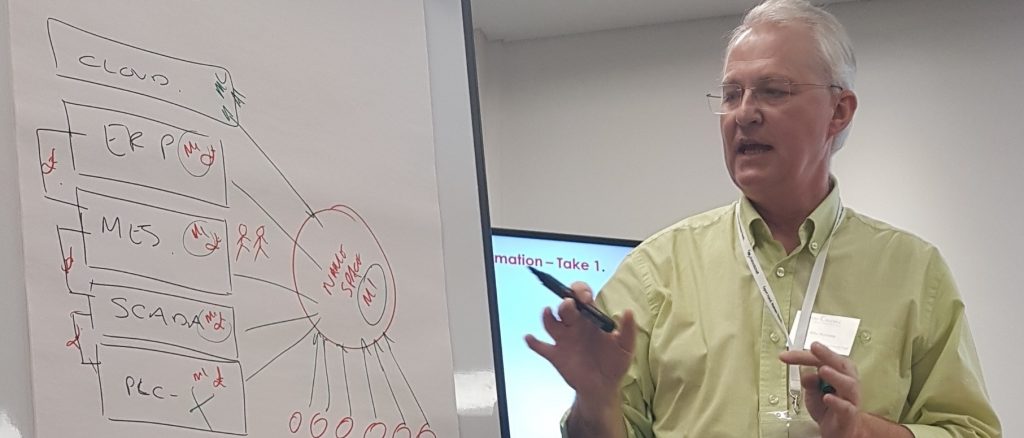

As the dust settles after busy preparation for the first Northern Crucible meeting of 2020, here are some reflections and observations. In this event, we have placed our focus on Industry 4.0 and legislation surrounding it. The presentations included an in-depth overview of Industry 4.0. Mike Burrows from RS Components gave an insight to their first forays into rolling out this technology, what challenges the company faced and how they were overcome. Mike also discussed what was achieved as a result of implementing Industry 4.0. It was a very hands-on perspective on the challenge itself and on how it can be broken down to sizable chunks and implemented in a real-life factory scenario.

Irwin Mitchell also delivered three talks: one on why we gather more data and how this data gets used; the second talk was about personal data and how the government is more likely to support claims of individuals on misuse of data by large companies. The third talk focused on types of cyber-attacks and risks involved. For every risk, a defense strategy was offered.

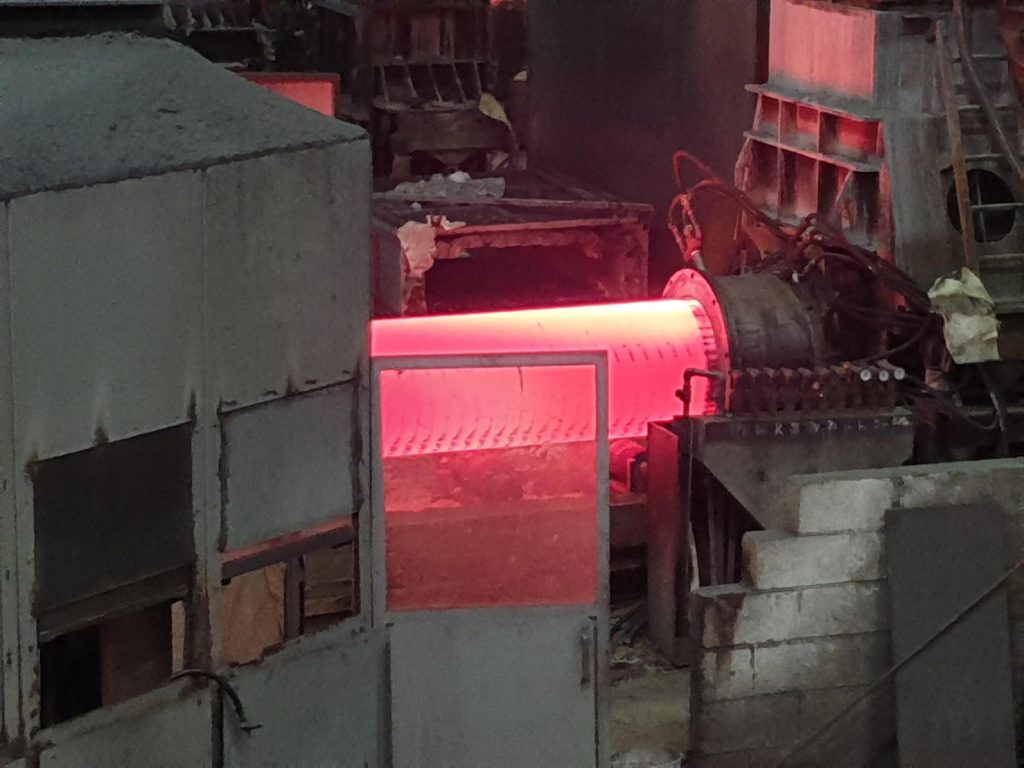

The topic of the event (Industry 4.0 and connectivity) was particularly well received by the local heavy industry contingent in the meeting. This sector faces strong realisation that implementing Industry 4.0 principles can turbo-charge their processes. Several attendees from metal industries have written in with positive feedback of how relevant and timely the meeting was. Some key points everyone agreed on:

- The companies who learn and use Industry 4.0 will survive the next decade. Those who cannot cope, will downsize or even disappear

- Training is the key to success. The biggest restriction to progress was board level not understanding how to roll this out. Even IT leaders, who had not kept up-to-date, were being left behind

- A large amount of security risks was through lack of simple training

- 49% of companies have been security breached. Cyber-security is the key to safe processes

This event was kindly hosted by Irwin Mitchell at their headquarters in Sheffield.

Irwin Mitchell is a full-service law firm with 15 sites in the UK. With over 1000 attorneys, it is one of the largest law firms in the UK. This event was supported by their manufacturing legal team. Also joining us on the night, was RS Components, a global trading company supplying electronic components and equipment. They have a worldwide turnover over £2.4 billion and are part of UK manufacturing supply chain backbone.